Fuel

Delivery

Index:

Introduction:

Damage Found:

ECU

Upgrade:

Fuel Pressure Gauge:

Boost-A-Pump:

HKS Vein Pressure Converter:

Injector Upgrade:

Split Second Unit:

Super

AFC

Fuel Management Unit:

Free

FMU

Split Second ESC1:

Final Recomendations:

Introduction:

I was very excited about my new

TRD supercharger until I started having problems.

Once problems started to surface I began testing to

try to tack them down. There is no doubt in

anyone’s mind that there is definitely enough

air being supplied by the supercharger, but the

question is whether the stock fuel system is up to

the increase in demand to provide enough fuel to mix

with the extra air being stuffed into the engine.

I have uncovered what I believe

to be some short comings and some possible solutions.

Back to Index

Damage

Found:

Before I installed the

supercharger my 4Runner could easily reach the 108

mph speed limiter built in to the ECU. After

installing the supercharger I had much more power and

acceleration until I reached 90 mph when I started to

loose power. If I backed off of the throttle slightly

it seemed to have a little more power. This is a classic sign of fuel starvation.

About a month later I developed

and exhaust leak at the front O2 sensor gasket and

the front cat gasket. I tore it down to replace the

gaskets and found that they had been burned through.

Not just from erosion from a ongoing leak, but BURNED

through! It takes a lot of heat to burn through these

type of gaskets especially so far from the engine.

Back to Index

ECU

Upgrade:

JET ECU Upgrade:

I

was looking through the Performance Products catalogue and saw the

listing for the JET Chip. It claimed a 17HP increase.

Well that sounded great.

I

visited a friend who owns a auto salvage chain. He

was able to get a spare ECU for my 4Runner. I

installed it in my 4Runner to verify that is worked,

and then sent it off to JET. I had it back the second

day.

I

installed it and took it for a drive. I was very

disappointed that I did not notice any difference. I

called JET to inquire and was told it takes 100 miles

for the computer to adjust itself. I drove for quiet

a while and never really noticed a difference. I even

swapped back and forth with my stock ECU and still

could not notice any difference in the way it

performed.

I

do not recommend the JET ECU upgrade.

E

L Prototypes ECU Upgrade:

The one on the left is a stock ECU,

the one on the right is the ELP modified ECU. You can

see the extra ROM board that is added in the upper

left corner.

I was really

impressed with the overall performance of my

supercharger equipped 4Runner, but I did notice it

started to loose power at about 90 MPH. It also would

struggle to meet the 108 MPH speed limiter programmed

into the stock Electronic Control Unit (ECU) in

overdrive. It seemed to me that it might not be

getting enough fuel and the mixture was leaning out

causing a reduction in power.

E. L. Prototypes (ELP) developed a

special ECU program for use with the TRD

supercharger. I was leery about ECU upgrades due to

my experience with the JET chip. I new that Ron was

sending his off to have it reprogrammed by ELP and

wanted to see what results he had. After getting his

back he had nothing but good things to say about it.

I then sent my spare ECU off the ELP.

I have been

told that the stock chip in the Toyota ECU "CAN

NOT" be reprogrammed. The chip has to be removed

and replaced. The Stock ECU does not have a removable

chip like on many of the domestic units.

Look at the

picture above. The one on the left is a stock ECU and

the one on the right is a modified by ELP. What ELP

does is remove the top left chip and replace it with

a ROM board. This new ROM board is equipped with a

removable chip or EPROM. The nice thing is that if

you make changes to you truck you can have a new

program developed and sent to you on a pop in chip.

The ECU really

improved the way the truck ran. It had a dramatic

increase in low and mid range torque and was much

more responsive. This was all without any boost.

Under boost it is a real screamer. It accelerates

very strong well past the old 108 MPH speed limiter

(removed). I can not tell you what the top speed is,

but I can say I left a Mustang and a Firebird behind

at 124 MPH and just walked away from them.

The speedometer

will peg on the odometer rest button at 115 MPH, so

you will have to watch the highest obtained RPM on

the tachometer. Then drive at half that RPM and read

the speedometer and then double it to get the top

speed.

I strongly

recommend that anyone who installs the TRD

supercharger on a 95-97 3.4L also have his ECU

modified by ELP. The ELP modification really works,

and works well.

Back to Index

Fuel

Pressure Gauge:

This started me wondering if

the engine was getting enough gas to meet the needs

of the supercharger. I installed an Auto Meter fuel

pressure gauge (see the section on gauges for more

information). What I

saw on this gauge is at about 4-5 psi of boost the

TRD Fuel Management Unit (FMU)would kick in and jump

the fuel pressure up to 65 PSI, so far so good. As

the RPMs continued to climb the fuel pressure would

drop. At the point of maximum demand the fuel

pressure would drop below 50 PSI which is only 7 PSI

over the idle pressure. If you then subtract the

amount of boost from the fuel pressure it places the

actual fuel pressure below the idle fuel pressure

(more on that later).

I spoke to the folks at TRD

about my fuel pressure loss and I was told that the

supercharger only needs 53 PSI for proper operation.

I told them all I was able to maintain was 50 PSI.

The guy had no more answers for me. So, yes, it is

leaning out! I knew I was going to have to fix it my

self.

Back to Index

Boost-A-Pump:

The FMU ups the fuel pressure

so that more fuel can flow from the injectors under

boost. The problem that I saw is that the fuel pump

is not able to flow enough fuel to meet the demands

of the supercharger. As a result as the demand would

go up the supply of fuel would go down causing the

mixture to go lean. This causes the exhaust gas

temperature (EGT) to go way up and power to drop off.

I installed a Kenne-Bell

Boost-A-Pump (BAP). The BAP works by increasing the

voltage to the fuel pump under boost causing it to

spin faster and deliver a greater volume of fuel. The

BAP has a control knob that allows you to adjust the

percentage of voltage increase to the pump. The BAP

is activated by a pressure switch mounted in the

supercharger plenum that activates at 3 PSI of boost.

I adjusted the voltage with the control knob so that

once the FMU kicked in I could maintain the 65 PSI of

fuel pressure. This was 35% on the control knob.

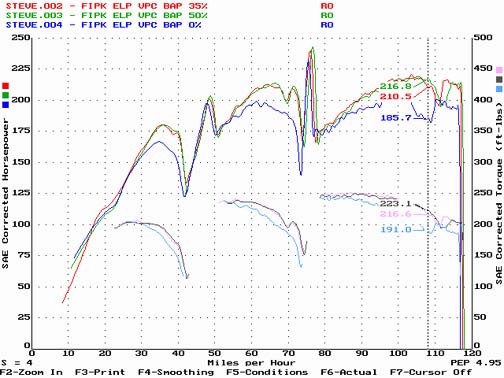

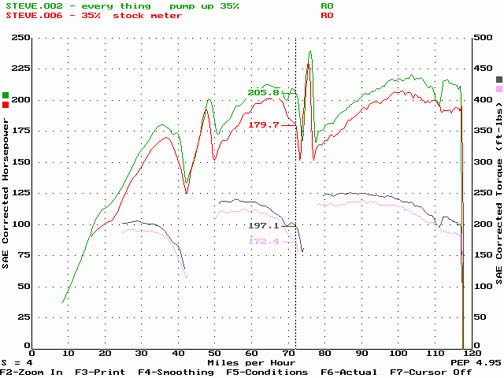

I made a trip to the dyno and

tested the results. I was amazed to see just how much

it increased the HP where without the BAP it would

drop way off. My dyno tests showed that a setting of

35% was ideal for the best power.

I called Mr. Bell at Kenne-Bell

to discuss my results. Mr. Bell was very familiar

with the TRD supercharger and that made things much

easier. He confirmed what I suspected that

supercharger was running lean.

Mr. Bell told me that there is

a very easy test you can do to see if your

supercharger is running to lean or not. Run a tank of

93 octane pump gas and then run your next tank with

100 octane unleaded racing gas. If you see an

increase in performance you are running lean. If the

performance stayed the same you are just right. If

you lost power your are to rich.

Here is what is happening. The

higher the octane the slower the gas burns. The

richer the mixture the slower the mixture burns. The

leaner or the lower the octane the faster it will

burn. Also the leaner it is the more likely it is to

cause detonation. When the engine starts to detonate

the knock sensors picks this up and the ECU retards

the timing. For every degree of timing retard you

loose about 3 HP. When you richen the mixture you are

suppressing detonation and this allows the ECU to run

the timing more advanced so you get better

performance. The BAP allows you to maintain a richer

mixture where before it was leaning out due to fuel

pressure loss.

As you can see

there is a very dramatic increase in performance.

These tests where done with the following setup:

K&N FIPK, VPC, and ELP ECU.

The results speak

for them selves. In the second gear pull showed 33.9

HP increase. In the third gear pull where the red

line starts dropping badly there is an increase of

31.1 HP

Exhaust Gas

Temperatures (EGT) where as follows:

Run 4 (BAP 0%)

peak 1655

degrees F

Run 2 (BAP

35%) peak 1579 degrees F

Run 3 (BAP

50%) peak 1577 degrees F

What I found is

that with the BAP the EGT would stay in the mid 1400s

until the very end in each gear where it would

suddenly spike to the temperatures indicated with a

sudden reduction in fuel pressure. It showed up in

the charts as a dip in the line toward the end of

each gear pull. The runs without the BAP the EGT

stayed very close to the peak through out the entire

run.

I installed a digital EGT meter

in the right side exhaust header. This meter has a

recall function and would record the highest

temperature recorded during the dyno run.

I set the BAP to zero for the

first run on the dyno. The dyno operator saw the

incredibly high EGT and aborted the first run. He

then tried to talk me out of any further runs worried

about engine damage. I explained to him that I have

been running it like this for some time and wanted to

press on. He reluctantly agreed.

The run with the BAP set to

zero recorded an EGT of 1655 degrees F. The EGT was

also that high through out the whole run. On the next

run I set the BAP to 35% and the EGT meter showed a

stable EGT in the mid 1400s until just before each

gearshift where it would spike to 1579. On the next

run I set the BAP to 50% and there really was no

additional benefit. The dyno did record a maximum

increase in HP of 33.9 HP with the BAP.

Keep in mind that these runs

were done with the ELP ECU and the VPC that was

already adding extra fuel. I simply can not imagine

what the EGT was without the ELP ECU or VPC.

I do feel much better with the

reduction in the EGT. There is no doubt that my

engine will last much longer.

Back to Index

HKS

Vein Pressure Converter:

The stock air

flow meter is very restrictive. E. L. Prototypes is modifying an HKS Vane Pressure

Converter (VPC) from a Toyota Supra for use on the

3.4L. This unit uses manifold pressure, an inlet air

temperature sensor and a computer to replace the

restrictive stock airflow meter. In place of the

stock air flow meter, a three in pipe is inserted.

After

installing the VPC I noticed an immediate increase in

top end performance. I also found it that it takes a

little time to get the adjustments set so the vehicle

runs properly. Initial setting took about 10 minutes

followed by fine adjustments over the next few days.

Installation

involves:

- Removing

the stock restrictive air flow meter and

replacing it with a straight piece of

pipe.

- Installing

a temperature probe in the plenum. It

replaces a allen headed plug on the rear

of the plenum.

- Installing

a manifold pressure sensor which is

connected to the vacuum line going to the

FMU.

- Splicing

about six wires into the wire harness

coming from the ECU inside of the dash.

- Mounting

the control unit.

The black box on

the fire wall is the manifold pressure

sensor. The silver thing sticking out of the

gray supercharger plenum is the temperature

probe.

I

installed the control unit in the glove compartment.

I attached it to the roof of the glove compartment.

This works out real nice. It is out of sight unless

you stoop down and look up and provides easy access

to the controls.

The

VPC Control unit has four knobs: Response (works

like an accelerator pump), Gain (overall

mixture), Idle (idle mixture). The fourth knob is

the "Option Out" knob. This is for

piggy back HKS computers like the F-Con, or the

GCCII. It is not used in my application.

There is a

hesitation that remains after setting all the

adjustments. This hesitation only occurs when pulling

off from a complete stop with a rapid throttle input.

I have tried everything possible to reduce the

hesitation. I spoke to Eric at E. L. Prototypes and

he agrees that it is most likely a slight bug in the

program. Eric has sent me a total of four different

chips and still the hesitation remains.

I have upgraded

my fuel injectors and because I have not been able to

get a new program to properly control the injectors

from E. L. Prototypes, I have had to replace the VPC

with a Split Second unit.

Back to Index

Injector

Upgrade:

Left

is the 270 cc Lucas injector, center is the stock 238

cc injector, and right is the 305 cc Toyota injector.

It was clear that I still was

not getting enough gas into the engine. Remembering

back to my first set of dyno runs the dyno operator

told me I needed an injector upgrade. He pointed out

the jagged saw tooth look to the lines on the chart

and said every time he has seen this it ended up

being to lean.

I sent one of my stock

injectors to RC Engineering and had it flow tested. It flowed at

238 cc. That means that when locked full open it will

flow 238 cc of fuel per minute. Locked full open is

100% of its duty cycle. The maximum recommended duty

cycle of any injector is 80%. This is the industry

standard to prevent erratic injector operation.

I used the fuel flow formulas

on the RC Engineering web page and computed the max HP for

the stock injectors out of my truck. At 80% duty

cycle they will support 198 HP and at 100% they will

support 247 HP. The 198 HP seems real bad and the 247

sounds a little more acceptable if the ECU will run

the injectors at 100% duty cycle.

I called E L Prototypes and

spoke with Eric the owner about my project. He told

me that he had just installed injectors out of a 95

GS300 in his drag 4Runner. He had developed a new

chip for the VPC he is marketing that would control

the GS300 injectors. He said he would send me the

chip to try out and if needed make me a new chip

specifically for my size injectors.

I ordered the 270 cc Lucas

injectors from RC Engineering. To install them I had to modify the

wire harness connectors as the Lucas injectors use a

different plug. At this I had previously removed the

HKS VPC due to drivability problems and was hoping

the ECU was capable of handling the new injectors by

its self. The ECU could not control the new injectors

effectively and tripped a check engine light.

I reinstalled the HKS VPC with

the new injector chip. The chip was for injectors

that where bigger and it ran to lean. I switched back

to the original chip and it ran to rich. I called

Eric and he said he would make me the chip I needed.

Eric has many projects in the works and it was taking

forever.

I was asked to try the Split

Second MAF conversion

kit. I installed the unit and was really impressed.

It dialed in the injectors nicely.

The 270 cc injectors really

made a big difference. It was making lots of power

and the EGT was way down. The problem I was now

having was with the TRD FMU that came with the

supercharger kit. With the FMU connected it would run

to rich at times due to the large rise in fuel

pressure. With it disconnected it would run to lean.

Thats right it would run to lean with 270 cc

injectors without the FMU. You folks with stock

injectors and no FMU on your TRD supercharger better

re-read that a few times.

After a long talk with Mr. Bell

at Kenny-Bell superchargers I was convinced that all

forced induction engines needed an FMU of at least

1:1 ratio. See the FMU section on this page for more

information on FMUs. I knew I needed an FMU but I

also knew that the 270 cc injectors are not big

enough for a 1:1 ratio FMU. I needed still larger

injectors.

I did some math and figured that a fuel

injector in the range of 300-320cc would be the perfect size

injector for my needs. I looked at different Toyota

applications and learned that the 95 GS300 used a 305cc

injector. I obtained a set and had them flow tested and they

were 305cc. Toyota

dealerships and they provided me with a Toyota part

number of 23209-46031 and said

this is the same injector used in the following

applications:

- 93-98 Toyota Supra

NON-turbo

- 94-97 Lexus SC300

- 93-94 Lexus GS300

California Emissions

- 93-97 Lexus GS300

Federal emissions

There is a guy (I am not going

to use his name so he will not get into trouble) I

know that works in one of the Toyota parts

distribution centers and I was able to get two sets

of these injectors at dealer cost. It was a one-time

deal. One set was for Ron S one for me. I sent the

injectors to RC Engineering and had them flow tested. They flowed

at 305 cc. I was kind of disappointed that they were

not 330s and was told by RC Engineering that

Eric’s injectors were flow tested at 312 cc.

I went ahead and installed

them. I also installed a Cartech model 20005 FMU that is completely

adjustable for onset and rate of rise so I could test

different fuel pressures to determine the ideal fuel

pressure for these injectors.

The first test drive showed I

had the perfect size injectors for my truck. I was

able to back down the FMU down to as close to a 1:1

ratio as I could get and the injectors were working

just fine. I was able to tune the Split

Second so that it idled

fine and at full boost I was able to get the EGT

right at 1400 degrees F. My prior dyno testing showed

that this EGT was the best power for my engine. With

this EGT my air/fuel ratio meter was indicating a

ratio of 13.2:1 as indicated by the first blue light

solidly lit on my Split

Second air/fuel ratio

meter.

Split Second ARM1

I called Magnuson Products, the people that make the supercharger

kit for TRD and they confirmed the ideal EGT for this

engine at max boost is 1400-1450 degrees that made me

feel great. I then called Split

Second and to talk to

them about the best air/fuel ratio. Split Second has

been doing some development work for TRD by the way.

They confirmed that the air/fuel ratio that I was

running is ideal for my application. So I feel very

confident that I have exactly the right size

injectors for my truck.

I do not see any need to go any

bigger. I have the high control on the Split

Second dialed way back

so I think that there is still plenty of room left in

these injectors. I wish I had a duty cycle tester to

see at what percentage of the maximum duty cycle on

the injectors are at full boost.

I also think that my 270 cc

injectors would work if I used them with the tunable Cartech FMU. It may just be a matter of finding

the ideal ratio of fuel pressure to boost pressure. I

know that with the TRD FMU it would be to rich at

times so that would indicate that it is possible to

flow enough fuel from the 270 cc injectors with the

proper fuel pressure rise. I think I will leave that

to someone else to iron out.

So if you want to do what I

have done you do have a few options depending on the

money you want to spend. The first is choosing the

injector. The Toyota injectors that I am using will

snap right into the wire harness without any

modifications, but cost much more then the 310cc

Lucas injectors from RC

Engineering. So if you

are trying to watch your money I would have to say go

with the RC Engineering injectors. You also may be able to find

some used Toyota injectors out one of the vehicles

listed above. Before you install them make real sure

the coil resistance is 13.8 ohms. Toyota uses

injectors with different coil resistance and you must

use high impedance injectors of about 13.8 ohms or

you may smoke your ECU.

Split

Second ARC 1

Split

Second ARC 2

You will also have to use some

type of injector driver or controller. I am using the

Split Second 3" MAF conversion kit with an ACR2

controller. That will cost you around $1100 and replaces the stock air flow meter

(AFM). You can go a cheaper route and get the Split

Second ARC1 controller

which is designed to work with the stock AFM and

costs around $300. You can later upgrade to a Supra

AFM for more airflow and more power. For information

on the Split Second ARC1 go to the Split

Second web page and

down load their brochure.

Back to Index

Split

Second Unit:

I obtained one of Split Seconds MAF conversion

kits and installed in on my 96 4Runner. A custom air tube had

to be made.

This

is what the prototype installation looks like. I can

not wait to see the final version. JT says he is

making the production version out of spun aluminum.

I have been running upgraded injectors for some time and have been trying to

get a new chip for my VPC that was tuned for my new

injectors. Eric at E

L Prototypes has sent

me a total of four chips for my VPC and

none of them were quite right. Given time I know that

he will eventually nail it, but the problem with the

VPC is that any time you change something you have to

have a custom program done to match it. With the SS

you just dial in the needed changes with the control

panel and you are all smiles.

The vender I got the kit from sent me a wiring

guide that was totally wrong and I had to sort all that out

myself. After sorting out the

wiring connections I had the Split Second installed

and running. I went on a test drive and was simply

amazed on the difference in performance. The throttle

response was incredible as was the top end power.

Simply by snapping the throttle

I can break the rear tires loose at will. Low end,

mid range and top end response and performance is

simply perfect. This is the one modification that has

brought all of the others together.

This

is a picture of the three different AFMs side by

side. Left is the SS 3", middle is the SS

3.5", and the one on the right is the

restrictive stock AFM. You can see why the stock one

is so restrictive. That big thing in the middle

really cuts down on the space that air can flow

through.

I prefer

the stock airbox over the cone type filters mostly

for the noise reduction and I know the K&N type filters are

about the worse air filter on the market for filtration. The cone type filters is

very loud. Once I get it I will test everything on

the dyno and report the results.

I am sorry to

say that even with my 270 cc injectors I still can

not get enough gas into the engine to prevent a lean

condition without the FMU connected. More proof that larger

injectors are needed.

I

used an air temp sensor out of a Nissan to substitute

for the one that is built into the stock AFM that I

removed.

The stock AFM has

the induction air temp sensor built into the unit.

When the stock AFM is removed the stock air temp

sensor goes with it. JT takes the same approach that

Eric at E L Prototypes did with the VPC. He includes

a resistor that is spliced into the stock AFM

harness. This resistor tells the ECU that the

induction air temp is at 68 degrees all of the time.

I decided to see if I could find a replacement air

temp sensor that I could use as a substitute. Using

the voltage values listed for the stock air temp

sensor listed in the Toyota shop manual I set out

testing all the air temp sensors I could find. I

found that the induction air temp sensor on my 95

Maxima was a perfect substitute.

I visited the

Nissan dealer and found that new ones are $65. I went

to visit my friend at the junk yard. I got four used

ones and brought them home and started to test them.

Out of the four two were still good. I sent one to Ron and

installed the other in the prototype air tube and

spliced it into the harness.

I can not say that

I have noticed any difference at all over the

resistor, but I do feel better knowing that the ECU

is now receiving the proper data to make its

calculations from.

I spent some time

prowling the junk yards and picked up a flanged

3" composite AFM and a air tube from the 99 Ford

Crown Victoria. I cut everything off of the rear of

the stock air box and the air flow meter was a

perfect fit if it was turned upside down. I then

sealed it with silicone. I then cut down the air flow

tube and I also cut down the metal tube. Everything fit real nice and

looks as if was OEM. I transferred the electronic module from the 3.5" Split Second AFM to the

Ford AFM. The bellows in the air tube provide plenty

of stress relief to allow for engine movement.

With the opening I cut in the front of my air box this setup emits a very pleasant hum

from the front of the vehicle at idle. What I like

most about this set up is that it is very, very

quiet. I wanted to get away from the K&N cone filter for its lack of

filtration and the

noise it makes.

Although this todate was the best

setup I had installed, the ARC2 controller just did not have enough

precision for optimum tuning and it was removed along with the

MAF. I then went back to the stock MAF and used the APEX S-AFC

for a controller.

Back to Index

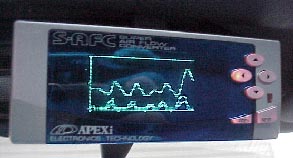

Apex

Super AFC:

I currently have

the AFC installed above my rear view mirror. It is easy to

tweak

it at stop lights. I am planning to move it to the glove

box soon.

There is a new device on the

market that works like the Split Second ARC units. It is made

by APEX and it is called the Super AFC. It operates on the

same concept as the SS ARC units by modifying the signal from the

MAF. By doing so you can alter the fuel mixture and dial in

larger injectors.

The thing that makes the AFC

different from the SS is that you can make the air flow corrections

at specific RPM and throttle settings and that can not be done with

the SS units.

The AFC is a very small compact

unit that makes installation much easier. It also has all

kinds of data displays like RPM, correction factor, throttle

position, air flow, and a few others.

I really liked how easy it was to

tune in. I had removed the Split Second stuff and replaced it

with my stock MAF and the AFC. The truck ran really good with

this combination, but I did loose some top end power with the more

restrictive stock MAF.

The Supra MAF is

easy to adapt to the stock airbox.

Because the mounting holes are on the opposite side as on the

stock MAF, I had to rotate it 90 degrees to the passenger side.

The nice thing is that it just plugs in to the stock harness.

It also has the IAT built in just like the stock one.

I was able to obtain a used MAF from a twin turbo Supra. It is

very much like the stock MAF on my 96, but much, much bigger.

It is very easy to adapt it to the stock air box. With the

larger MAF all the top end power came back. Overall I liked

this combination so much I sold my ARC2 and 3.5" SS MAF.

With the stock MAF and my 305cc

injectors, I had the low throttle settings on the AFC set at -15%

and the high throttle settings at -10%. The hot wire type is

set to 01 and 01. Works really nice.

I had to retune the AFC when I

upgraded to the larger Supra MAF. The low throttle settings

are, +20% and the high throttle settings are +35% and +40% at 4000

RPM and up. The hot wire type is set to 15 and 15. As

you can see with the larger Supra MAF the settings must be much

higher to compensate for the greater air flow through the larger

MAF.

The AFC is really popular in the

sport compact car scene and they can be hard to find. You can

shop around on the net and find one at a good price.

HKS has come out with a similar

unit called the AFR. I have made connection guide for several

people that got the HKS AFR and most all of removed them and

replaced it with the AFC. There is no graphic display and it

seems that people loose track of where their settings are. I

suggest that if you get one you plot your correction factors out on

some graph paper so you have something visual to look at during your

tuning. To date I know of one person that was successful in

getting the AFR properly dialed in, most of the rest hated it.

I have since removed the AFC and

upgrade to the Split Second Fuel Timing Calibrator (FTC).

Back to Index

Fuel

Management Unit:

TRD includes, or at least did,

a Fuel Management Unit (FMU). In theory what this

thing does is increases fuel pressure under boost to

cause more fuel to flow from the injectors.

The TRD unit is installed by

removing the stock fuel pressure regulator from the

fuel rail. The TRD FMU is then clamped on top of the

stock fuel pressure regulator. The FMU has a

diaphragm in it that is deflected by positive

pressure in the manifold (boost). There is a pin

attached to the diaphragm that pushes on the

diaphragm in the stock regulator causing it to hold a

higher fuel pressure then it normally would. The

combination FMU/regulator is bolted to the firewall

and the stock regulator is connected to the fuel rail

with a high-pressure hose. A vacuum hose connects the

FMU to the supercharger plenum.

By increasing the fuel pressure

you are forcing more fuel from the injectors into the

engine. Is this a Band-Aid fix for not having

injectors big enough to do the job, or does the FMU

just allow you to brake even?

I spent some time talking to

Mr. Bell at Kenne-Bell about supercharger fuel needs.

Mr. Bell is a wonderful guy and he is a real straight

shooter. It is his opinion that all forced induction

engines must have an FMU of at least 1:1 ratio of

boost to fuel pressure increase. He explains that if

your normal fuel pressure is 43 PSI and you increase

your boost is 7 PSI with no FMU you have a negative

affect on the fuel pressure and are essentially

reducing the fuel pressure by 7 PSI. As the pressure

increases in the plenum it restricts the fuel from

flowing from the injectors. In this example you have

a net affect on the fuel pressure by a reduction of 7

PSI so it is now 36 PSI. This further compounds the

lean condition. By the way TRD does in fact sell a

1:1 FMU as an upgrade for the turbo Supra.

Interesting don’t you think?

Here is the problem. Stock fuel

pressure regulators and fuel pressure gauges work by

comparing the fuel pressure in the fuel rail with the

pressure of the OUTSIDE air and not the pressure in

the manifold or plenum. This is fine for a normally

aspirated engine because the manifold pressure never

exceeds the outside or atmospheric air pressure.

Forced induction engines are different. As the

pressure in the plenum increases it has the affect of

decreasing the fuel pressure by the same amount

because it makes it harder to flow fuel from the

injectors into the plenum. This is where an FMU comes

in. It will adjust, or supposed to anyway, the fuel

pressure in relation to the pressure in the plenum.

A big problem that I have

observed with the TRD FMU is that it is very

inconsistent. If I quickly apply the throttle the TRD

FMU reacts very quickly and jumps up the pressure. If

I ease into the throttle the TRD FMU dose not react

until I get about 5-6 PSI of boost. This maybe why

some 4Runners ping under light acceleration. The

overall amount of fuel pressure increase is very

inconsistent and does not seem to have a good

relation to the boost pressure. In other words it is

erratic as hell. As the boost goes up fuel delivery

is being reduced until the TRD FMU kicks in.

TRD has deleted the FMU from

the newer supercharger kits. We have been told that

this was done to eliminate pinging on the 98 and

later models. From my testing and the very high EGTs

even when using the FMU, the thought of running the

supercharger without an FMU is real scary at best. I

wish TRD would replace the erratic FMU with a more

stable and consistent one instead of just getting rid

of it.

Ron has installed a Cartech FMU

that allows him to adjust the ratio of fuel pressure

increase in relation to boost pressure and the onset

of the increase. What that means is it can be

adjusted to a 1:1, a 2:1, a 5:1 or what ever you

want. Not only that, but you can adjust it as to when

the increase in fuel pressure starts. You can set it

to start as soon as you have boost or what until you

reach a certain boost level. Ron had such great

results that I decided to order one so that I could

test different fuel pressures with my new injectors.

The Cartech FMU is different

then the TRD FMU. It is not installed on top of the

stock fuel pressure regulator like the TRD one.

Instead it is installed in the fuel return line that

returns fuel from the regulator to the fuel tank. The

way this FMU works is that it restricts the fuel

leaving the stock regulator when needed to increase

fuel pressure in the fuel rail.

This FMU is ideally suited for

installation on the TRD supercharger kits with the

deleted FMU, or to replace the erratic TRD FMU. The

only thing is that you will have to replace the fuel

return hose from the regulator to the tank with a

section of high-pressure hose. Ron came up with the

idea of upgrading this hose is when the supercharger

is being installed. Because the newer kit do not

remove the regulator from the fuel rail the only way

to get to it is with the supercharger off of the

engine. Everyone installing the supercharger should

plan ahead and replace the return hose with a

high-pressure hose at the time of supercharger

installation. This way if you decide to install the

Cartech FMU after installation you will not have to

remove the supercharger to do so.

It is important to keep in mind

that there is no way a FMU can make up for the

injectors being to small. On the RC Engineering web

page Russ has an example using a 240 cc injector. By

upping the fuel pressure from 43 PSI to 50 PSI there

was an increase of only 2.64 HP worth of fuel flow

for that injector. Now if you subtract out the boost

pressure differential of say 7 PSI of boost you

really have accomplished nothing and really only

broken even.

Cartech

20005 FMU

I installed the Cartech 20005

FMU along with my new 305 cc injectors. I was hoping

that I would only need a 1:1 ratio of fuel pressure

rise to boost pressure. My tests confirm that with my

new 305 cc injectors a 1:1 ratio is ideal. I have

found that the Cartech FMU is a very nice unit and is

very consistent and reliable and will give the same

results time after time. It performs as it should and

not like the erratic FMU that was included with the

TRD Supercharger kit. Those of you that are still

running stock injectors and no FMU this would be a

good one for you to get. It installs in the fuel

return line from the stock fuel pressure regulator.

You will need to upgrade the line from the stock

regulator to the Cartech FMU with a high pressure

fuel injection hose as the stock return line is not

intended to hold pressure.

TRD

Supra fuel pressure regulator (FMU)

Now that I have confirmed that

a 1:1 ratio is ideal with the 305 cc injectors, I

replaced my Cartech FMU with this TRD fuel pressure

regulator. It is suposed to work just like the

Cartech FMU and is fixed at a 1:1 ratio. I installed

it and found out real fast it really is not any good.

I set it up just like the

Cartech FMU. I adjusted the onset screw with the

vacuum line disconnected from both the stock fuel

pressure regulator and the TRD fuel pressure

regulator so I noticed the slightest increase in fuel

pressure above the stock regulator. Then I locked the

jam nut.

I went for a test drive and

found that it does not provided a 1:1 ratio increase

in fuel pressure at all. It would increase fuel

pressure about 3 psi at the most. So with 9 psi of

boost indicated it would only increase fuel pressure

by 3 psi. It was not any good for my purpose and I

removed it and reinstalled my Cartech FMU until I

discovered the "FREE FMU".

Overall, I have had little luck using these

FMUs. They all proved erratic, inconsistent and totally

worthless. I am convinced that all these pressure increasing

FMUs are junk and are nothing more then a piss poor band aid

fix. The proper thing to do is to install the correct size

fuel injector and control them electronically.

Free FMU:

While testing the Cartech FMU

and the TRD Fuel pressure regulator I decided to see

if I could run my 305cc injectors without an FMU

stumbled across something. I removed the Cartech FMU

and went for a test drive. I was surprised to see

that my fuel pressure was increasing when I was in

boost at a ratio of 1:1. How can this be?

I checked out my connections

and found that I had the stock fuel pressure

regulator (FPR) hooked to the boost port. The stock

connection is to the main air induction tube which is

really nothing more then a vent and gives a constant

43 PSI all the time.

With the FPR hooked to the

boost port it will react to boost pressure and

increase the fuel pressure under boost at a perfect

1:1 ratio. This offsets the boost pressure

differential that I discussed earlier and really does

a good job of stabilizing the fuel pressure in

relation to manifold or boost pressure. The funny

thing is that all the other fuel injected engines I

have toyed with has the FPR connected to a port that

allows it to read and adjust the fuel pressure in

relation to engine load (manifold pressure).

Here is the benefit with the

TRD supercharger. Like I explained earlier, as the

manifold pressure increases in boost it will restrict

fuel flow from the injectors. By reconnecting the FPR

to the boost port you prevent this problem and it

will give you 6-7 PSI of extra fuel pressure at max

boost that you did not have before. Many people with

the dreaded pining problem have tried this and it has

in some cases eliminated the high gear, low RPM ping.

All have reported an improvement.

I do not think for a second

that this will be enough to prevent the fuel system

from leaning out at max boost, but it will not be as

bad.

Give it a try. It is FREE and

you can easily switch it back. I have been told that

TRD has heard about my little trick and is now

recommending it as their own discovery.

I currently have my stock FPR

connected to the boost port and I am using the 305 cc

injectors.

Back to Index

Split Second ESC1:

With the larger injectors and

the Split Second (SS) ARC2 controller I have solved

my top end fuel delivery problems. There was still

one spot in the power band I was not happy with. That

was part throttle acceleration under boost. In this

region I felt that the engine just was not producing

the power it should and there was a constant surging.

I figured out what was causing

the surging as soon as I installed my SS air/fuel

ratio gauge (ARM1). It is from the ECU operating in

"closed loop" operation. In closed loop

operation the ECU it constantly adjusting the fuel

mixture to try to find the "ideal" mixture.

The mixture is being varied from rich to lean, then

back to rich. This cycle takes about a second to

complete. When it is on the rich side there is more

power, when on the lean side there is less. So it

presents as surging in power. More proof that this

engine control system was not intended to support an

aftermarket supercharger.

At full throttle the ECU

switches into "open loop" operation and it

is no longer cycling the mixture. It switches over

and uses the full throttle fuel map, which is richer

then cruise power and it makes more power. It would

also switch into open loop if I continued to

accelerate in 3rd gear for about seven seconds or

more. As soon as it would switch into open loop the

surging would disappear and there would be a

noticeable jump in power.

I found I could adjust my SS

ARC2 so that it would be real rich in the mid range

while acceleration under boost with part throttle.

This would cause the ECU to switch into open loop and

would run nice in this narrow range, but would throw

everything else way out of adjustment. I knew what

had to be done, just not how to do it. I started

making calls and spoke to Eric at SS. He said that

they had just the thing I needed, the ESC1.

The ESC1 is a signal

conditioner. They make a few different ones that

modify the signal from the sensors to the ECU. This

one modifies the signal from the front O2 sensor.

Under boost it modifies the signal from the O2 sensor

to the ECU causing the ECU to switch into open loop.

There are 4 wires that get

spliced into the ECU harness, and a vacuum line that

is connected to the boost port. I found that the

connections have to be made behind at the ECU, which

it located behind the glove box. The O2 sensor wires

are shielded in the engine compartment to prevent

interference so you can not make the connections

there. I originally installed the ESC1 behind the

glove compartment. I had a loud buzz under boost. It

turned out to be whine from the supercharger

traveling up the vacuum line. I then followed a

friends lead and installed the ESC1 on the firewall

next to the wiper motor.

I went for a test drive and

found out right away, this thing is great! Shortly

after going into boost the ECU kicks into open loop

and I now have so much more power then I did before

at the lower boost levels. The surging is GONE. Now

for the very first time my supercharger feels like a

factory installed unit. It is very smooth and very

torquey at lower boost levels. It is amazing what

just a tad more fuel will do for the drivability of

the supercharger.

I live off of a long country

highway with lots of hills. Using the cruise control

was impossible due to all the downshifting. The

installation of the supercharger made that a lot

better, but it still down shifted more then I liked.

Now with the SS ESC1 the engine makes so much more

torque at highway speeds it no longer down shifts. It

climbs the same hills with 2-3 PSI less boost then

before. It is interesting to watch the boost gauge

suddenly drop 2-3 PSI as soon as the ECU transitions

into open loop.

I find that I can pass the slow

pokes hogging the left lane and that are too rude to

move over without down shifting. I just ease in the

throttle and get lots of torque and I can add 20 MPH

without down shifting so fast it feels like I have a

350 in it.

So, the SS ESC1 gets my seal of

approval. It works and does exactly what SS says it

will do. The ESC1 will work on all O2 sensor equipped trucks from

95-98. Starting in 99 Toyota started using an wide band O2

sensor on some truck and the ESC1 is not compatible with that

sensor. Still some trucks were equipped with the old style O2

sensor, but there is no boost induced power surging on the 99 and

later trucks so I do not recommend using the ESC1 on anything newer

then 98.

Back to Index

Final

Recomendations:

Fuel delivery solution has to

be done in a package deal. One thing without the

other is only a half assed approach. The first thing

is everything is dependent on there being enough fuel

available from the pump in the first place. You

should install a BAP or a larger pump so that enough

fuel will be available. I am using the BAP. Then you

have to find a way to get it into the engine. I have

chosen to install adequate fuel injectors. Another

approach is to install extra injector(S) in the

intake track. Then there must be a way to properly

control the injectors so the right amount of fuel is

injected at the right time. I am using the Split

Second Unit. And lastly you must make sure that boost

pressure is not going to restrict fuel flow from the

injectors by installing an FMU.

You also must be able to

monitor engine operation to make sure everything is

working properly. I did this by installing a Split

Second Air/Fuel ratio meter, a dual EGT gauge, and a

fuel pressure gauge. This allows me to cross check

engine functions and be able to spot a problem before

I melt a piston.

After everything I have learned

from my dyno testing I have developed the opinion

that the TRD supercharger kit runs to lean. I have

discussed my findings with several other supercharger

kit manufacturers and all have agreed with my

findings. The real kicker was a guy that worked for

the company that developed the TRD kit for TRD. He

says that he had told TRD that the kit in it current

form without the TRD FMU is to lean and that TRD has

flat out chosen to ignore him. He said, "it is the

most expensive way I have ever seen to aluminize an

exhaust system."

Update:

I have formed a company to market a fuel kit

based on everything I have tried, learned and developed to

date. This is a complete kit that includes everything needed

to solve the High RPM Lean Out problem, the HG/LR-ping, as well as

provide a very nice increase in performance.

I installed one on a 2001 Tacoma and dyno

tested better then a 40 HP gain.

Check it out at www.URDUSA.com.

Back to Index

|