This

is the original pulley plate with the two idler pulleys.

The original TRD

supercharger kit came with a pulley plate that had two idler pulleys

to guide the drive belt. Very soon after the release of the

first batch problems started to surface with drive belts coming off

or failing. TRD as a fix modified the pulley plate so that it

only had one idler pulley. It is hard to believe, but fewer

guide pulleys seemed to work better.

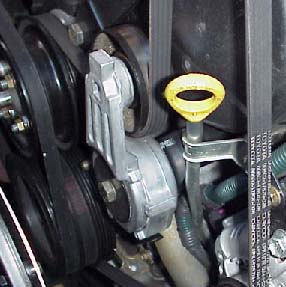

This

the later pulley plate with the single pulley

The problem was setting the

proper tension of the drive belt. The newer flat ribbed belts

require much higher tension then the old V belts to work

properly. There is a gauge called a belt tension gauge that

you should buy to properly set the belt tension, but they are

expensive and sell for around $100. Belt problems seemed to

always plague the supercharger because people just would not spend

the $100 for the proper tools and it seems that the dealers that are

supposed to have them many times don't. If the belt is to

loose it will slip, wear out faster, and may jump off the

pulleys. If it is to tight then it put excessive load on the

bearings in the supercharger nose drive, idler pulleys, and

alternator. There is a very fine line between to tight and to

loose, neither is a good thing.

Here

is the new TRD "Dynamic Tensioner" installed.

The latest kits are now

including a spring loaded supercharger belt tensioner. The

tensioner is available as an upgrade for the older kits. In the past you needed to

obtain a belt tension gauge that can cost as much as $100 to properly

set the belt tension. In theory the new tensioner handles

this problem for you. However, the installation guide still says

that a belt tension gauge should be used to set the initial tension of

the belt. The alternator can be moved in and out to

adjust the belt tension on a stock engine and if it is to far in or

out it will prevent the new tensioner from holding the proper

tension so it must still be initially set using the gauge and from

then on it should be fine. I found that with both of

retrofit dynamic tensioners that I installed on my 4Runners I did

have to use the belt tension gauge to properly set the tension to 80

Lbs-Ft of tension. This was even with the tension properly set

with the pulley plate.

The

tensioner comes with two brackets, one if for relocating the

wire harness that is behind the tensioner, and the other is to

relocated

the oil dipstick tube. You will need a torque wrench to install

the tensioner.

I have obtained a retrofit

dynamic tensioner and installed it. It is a very nice unit,

however I think I see potentially a serious problem with it. On

the original kits a steel pulley plate was bolted to the engine block

and the nose of the supercharger. This served two purposes.

One it held the guide pulley or pulleys for the belt depending on

which version you have; and two it supported the nose of the

supercharger. This plate is removed with the dynamic tensioner

and now the nose is not supported. The belt puts a high load on

the nose of the supercharger along with the weight of the supercharger

assembly its self. The mounting points on the manifold are in

cast aluminum. The mounting point is a fair distance from the

load. It is a matter of leverage here. I am convinced that

the mounting points are not strong enough to carry this load and the

mounting bolts will eventually pull out of the cast aluminum.

The bolts are only torqued to 13 lb-ft to prevent them from stripping

so they can't be very strong.

I

took my old single pulley plate and cut it along the line and

removed the pulley part.

This worked great for supporting the nose of the supercharger and

provide enough room

for the new dynamic tensioner pulley.

As

you can see in these pictures my modified bracket supports the

front of the supercharger nicely.

Out of concern for what I

believe to be a problem I cut up my old pulley plate so it will clear

the dynamic tensioner and installed it so that it still supports the

nose of the supercharger. This may or may not be a problem, but

I have always said "careful never hurt nobody."

The single pulley plate is

available from TRD through your local dealer. It is surprisingly

cheap for a TRD part and is much easier to get one and cut it then

to make your own supercharger support. You may want to act

fast because they may stop making and stocking them with the release

of the dynamic tensioner.